10. How to Choose the Right Laser Welding Machine for Your Needs

Introduction

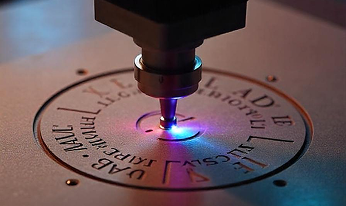

Any manufacturer must make a significant decision when purchasing a laser welding machine. Given the wide range of laser technologies, machine configurations, and automation levels available, it's vital to understand how to match the appropriate machine to your production needs. Poor weld quality, low production, or expensive downtime can result from using the incorrect system.

We'll go over the most important things to think about in this guide when selecting a laser welding equipment so you can make an informed choice that will provide accuracy, productivity, and return on investment.

1. Specify Your Needs for Production

Assessing your production demands in-depth is the first step before delving into machine specifications. This evaluation will influence all subsequent decisions:

- Type of Material:Choose between metals (steel, aluminum, copper, titanium), alloys, and even non-metals (plastics) for the welding process.

- Material Thickness: It's critical to consider the thickness range of your workpieces. The amount of laser power needed for thick plates and thin sheets varies significantly.

- Manufacturing Volume:While high volume manufacturing necessitates automation and speed, low volume applications could profit from simpler methods.

- Weld Quality Requirements:Ultrafast or fiber lasers may be necessary to provide the faultless, aesthetically pleasing welds required by some applications, such as aerospace or medical.

- Operational Mode:Will manufacturing lines use a completely automated procedure, a semi-automated one, or a manual one?

You can prevent overspending or underbuying by establishing these criteria precisely at the start and reducing your equipment choices.

2. Selecting the Right Laser Type

Selecting the appropriate laser type is essential because every technology has unique benefits and drawbacks.

- The most adaptable choice for metals is fiber laser. provides quick, deep welding that uses little upkeep and a lot of energy. Perfect for heavy industries, electronics, automotive, and aerospace.

- For non-metallic materials like plastics and textiles, CO₂ Laser technology is still used despite its age. Ultra-smooth weld seams in thin metals are another benefit.

- Hybrid Laser: For structural steel and big components with imperfect fit-ups and gaps, this technique combines laser and conventional welding (MIG/TIG).

- Ultrafast Laser: Provides incredibly accurate microwelding without causing harm to components that are sensitive to heat. utilized for luxury products, technology, and medical devices.

3.Align Power Output with Application

Laser power impacts your ability to achieve sufficient penetration and speed. It is crucial to select the correct power range for your application:

| Application | Suggested Power Range |

|---|---|

| Thin sheets (0.1–2mm) | 500W–2kW |

| Medium thickness (2–6mm) | 2kW–6kW |

| Thick plates (6mm+) | 6kW–20kW+ |

- Thin Materials: Burn-through and significant heat distortion are avoided with lower power.

- Medium to Thick Materials: To attain high travel speeds and deep penetration, more power is required.

- Extremely Thick or Specialty Materials: Fiber lasers with ultra-high power or hybrid techniques would be needed.

4. Consider Machine Configuration

The machine format needs to match the manufacturing environment and the geometry of your product:

- Manual or Handheld Systems:are ideal for workshop use, small-scale manufacturing, prototyping, and maintenance.

- Semi-Automatic Benchtop Systems:are perfect for fixtures, tiny parts, and moderate production volumes.

- Fully Automated Robotic Cells: Necessary for large-scale manufacturing with intricate pathways, speed, and reproducibility.

- Applications using big components, such as panels, structural frames, and industrial enclosures, employ custom gantry or cartesian systems.

When it comes to labor cost savings, stability, and throughput, automated equipment provides the best long-term value.

5. Assess the Needs for Automation and Integration

Data and communication are essential to modern industries. Ensure that the following important technologies are supported by your laser welding machine:

- Automated control and reproducibility are made possible by CNC control and parameter management.

- Multi-axis robotic arms for managing intricate weld geometries are supported by robotic integration.

- AI-powered technologies that modify parameters in real time to achieve flawless welds are known as seam tracking and adaptive welding.

- Integration of MES with ERP: Enables production planning and real-time monitoring.

Purchasing machines that are future-proof helps you avoid later, expensive updates.

6. Assess Software and User Interface

Operational simplicity is equally as crucial as machine hardware:

- User-Friendly Controls: Pre-set programs, clear menus, and touchscreen displays all help to minimize operator error.

- Data Logging: Monitor process variables for traceability and quality control.

- Supervisors can keep an eye on production from a distance thanks to remote monitoring.

Modern software guarantees process dependability across operators and shifts while lowering the need for training.

7. Total Cost of Ownership (TCO)

Only a portion of the calculation involves the purchasing price. Think about:

- Energy Consumption: Compared to older CO₂ systems, modern fiber lasers use a lot less energy.

- Consumables:Shielding gas, nozzles, and optics should be replaced on a regular basis.

- Maintenance: Service agreements, preventive maintenance, and the possibility of downtime.

- Operator Training:Skilled personnel may be needed for complex machinery.

By calculating TCO, you can make sure your investment is lucrative and your budget is accurate.

Conclusion

Aligning technology with your production demands is key to selecting the best laser welding machine. You will get the best return on your investment if you choose a machine that strikes a balance between accuracy, speed, flexibility, and overall cost.

- Clearly state what you require.

- Choose the appropriate laser strength and type.

- Select the appropriate automation level and machine setup.

- Assure minimal TCO and user-friendly software.

From fiber laser systems for high-speed industrial production to ultrafast lasers for ultra-precise applications, Laser Technologies India provides a comprehensive range of laser welding solutions, supported by professional consultancy to assist you in making the best decision.

"How to Maintain & Troubleshoot a Laser Welding Machine" is the next topic covered at Laser Welding University.